China’s Dark Factories The Future of Automated Manufacturing

China’s Dark Factories: Manufacturing Without Lights or Humans

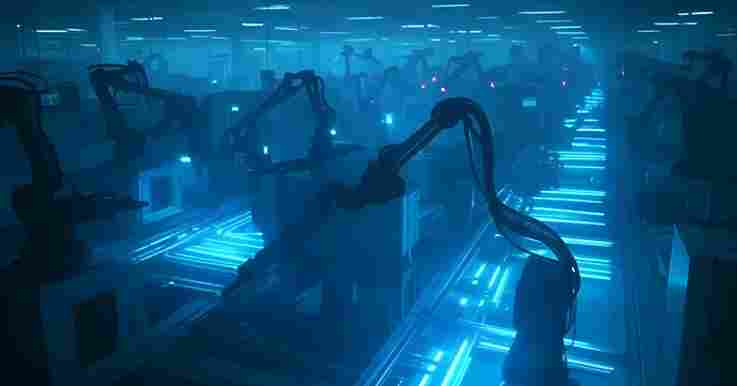

Imagine a factory that runs 24/7, in total darkness, with no humans on the floor. Welcome to China’s “dark factories” — a new frontier in smart manufacturing where robots, AI, and automation take center stage.

These factories are designed for maximum efficiency and minimal human involvement. Robots assemble, pack, and move products with precision, monitored by AI systems that ensure quality control and real-time data analytics. Since no workers are required on the floor, even lighting is unnecessary — hence the term dark factories.

Why Dark Factories Matter

- Efficiency: Machines work non-stop without breaks, fatigue, or shifts.

- Cost-Effective: Reduces labor costs and human error.

- Scalability: Systems can rapidly adjust to demand or changes in production.

- Predictive Maintenance: AI detects faults before they happen, reducing downtime.

- Global Competitiveness: Positions China as a leader in smart manufacturing.

Industries Already Using Dark Factories

- Electronics Manufacturing

- Automotive

- Logistics & Warehousing

- Medical Device Production

What It Means for the Future of Work

While this level of automation can boost productivity, it also raises questions about job displacement, reskilling, and the role of humans in future economies. The shift toward “dark” production floors means that soft skills, innovation, and tech literacy will become increasingly vital in the job market.

FAQs

Q1: Are dark factories completely human-free?

A: While robots handle the majority of tasks, humans are still needed for oversight, maintenance, and strategic planning.

Q2: Are other countries adopting this model?

A: Yes, countries like Japan, Germany, and South Korea are also investing heavily in smart factory models.

Q3: What are the challenges of dark factories?

A: High upfront costs, cybersecurity risks, and complex system integration.

Final Thought:

China’s dark factories are more than a technological feat — they’re a symbol of where manufacturing is headed. As automation evolves, so must our skills and understanding of the digital economy.